Label navigation

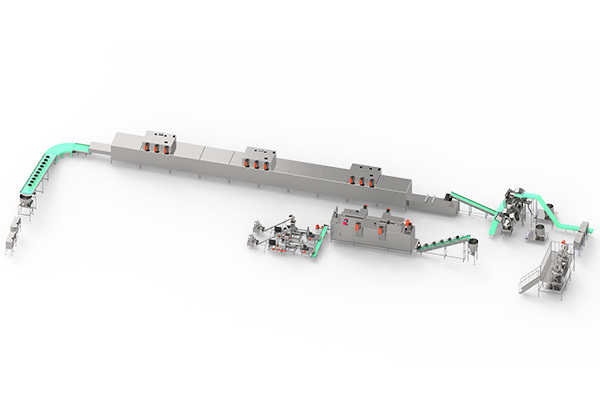

Bugle Doritos Production Line

The Bugle Doritos production line is a comprehensive and highly coordinated system for mass - producing Bugle Doritos. It starts with the intake of raw materials such as cornmeal, seasonings, and other ingredients. These are carefully measured and mixed in specific ratios.

Product content

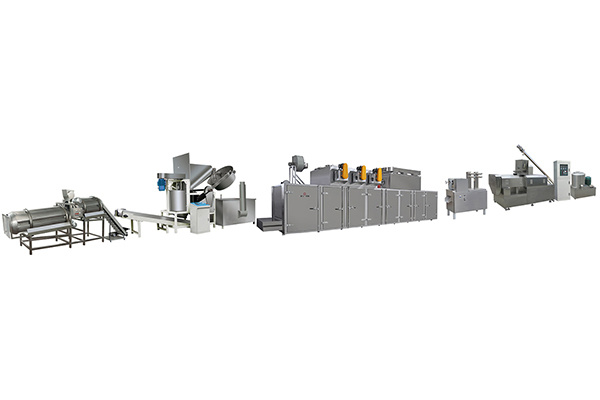

Breakfast Cereal Production Line Corn Flakes Making Machine

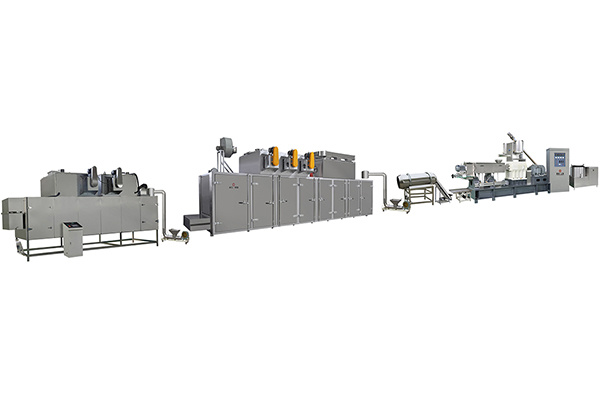

The breakfast cereal fruit oatmeal and oatmeal production line uses corn flour, wheat flour, oat flour and other grains as raw materials, and is extruded by a twin-screw extruder to make rice grains, circles, and small grains. After roasting and drying, it can be made into cereal breakfast products; it can also be pressed into flakes by a tablet press, and then dried and high-temperature secondary puffing can be made into flake cereal breakfast products such as corn flakes and oatmeal. The production line has a high degree of automation and stable production. The cornflakes, oatmeal, oatmeal, puffed rice and other cereal breakfasts produced can be eaten immediately after opening the bag or brewed with milk or hot water. They are both delicious and nutritious, and are well received by consumers at home and abroad. favorite. The entire assembly line is reasonably matched, and can realize the whole process control, so that you can produce nutritious and delicious breakfast cornflakes while improving efficiency, reducing costs and improving market competitiveness.

隐藏域元素占位

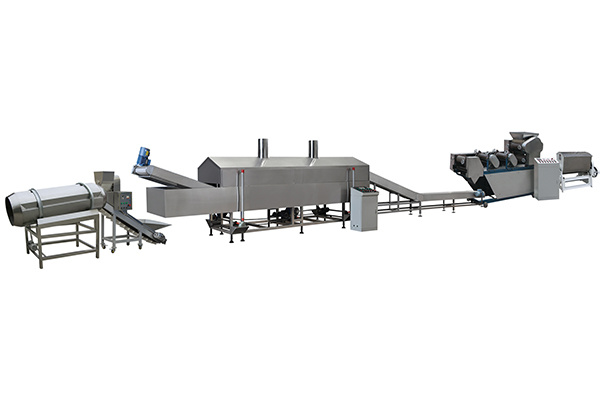

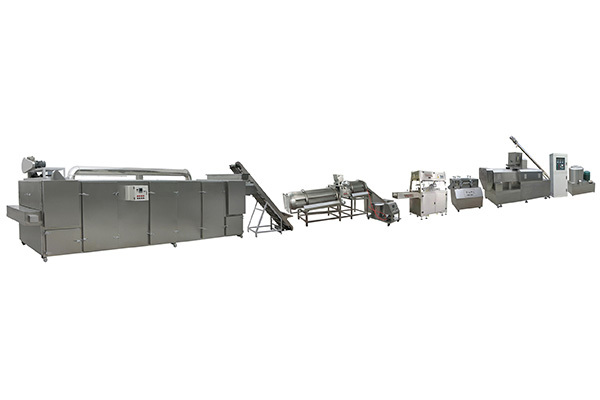

The fried pasta production line uses flour, corn flour, corn starch, tapioca starch and potato starch as raw materials, changes different molds, and is directly extruded by a twin-screw extruder to cut into special-shaped composite products such as strips, flakes or triangles. Fried and seasoned to make crispy, delicious, fine-textured fried puffed food The production line is automatically completed from mixing, extrusion, to frying and seasoning. The configuration is reasonable, the degree of automation is high, the performance is stable, the shape of the produced product is more realistic, the texture is more delicate after frying, and the taste is crispy. Our screw combination technology and precise control of the production process enable wider selection of raw materials, better product quality and more varieties.

隐藏域元素占位

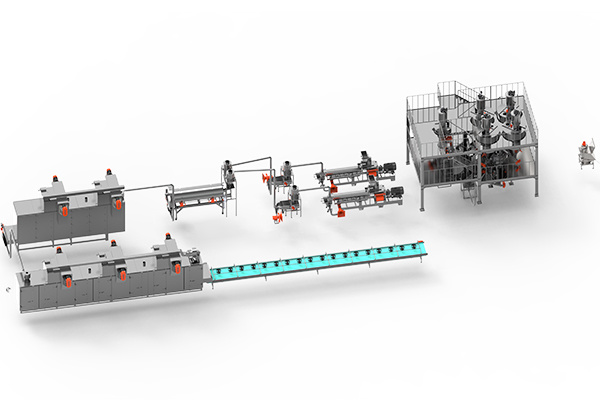

Fried crispy rice, salad bar, Miao crispy corner production line

The production line of deep-fried crispy rice, salad bars, and crispy crispy is a new technology that uses twin-screw extrusion technology to replace the traditional steamed rice crispy production. The production line integrates raw material mixing, cooking, ripening, puffing, molding, frying, and seasoning, and does not require a boiler. The production process is simplified, efficient, and environmentally friendly; the raw materials can be rice flour, corn flour, flour, etc. These mixed materials; the shape of the product can be changed by changing the mold, and the produced pasta crispy rice, salad, etc. are crispy and not greasy, and are widely loved by consumers.

隐藏域元素占位

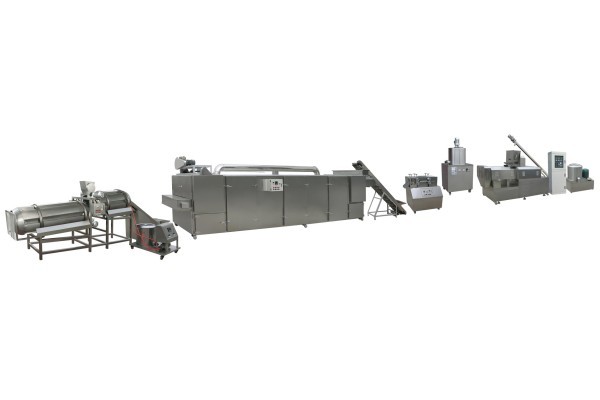

Fried tartary buckwheat flakes, buckwheat flakes production line

The fried puffed food production line uses flour, corn flour, corn starch, tapioca starch, potato starch, etc. as raw materials, changes different molds, and is directly extruded by a twin-screw extruder to cut into special-shaped composite products such as strips, flakes, or triangles. Fried and seasoned to make crispy, delicious, fine-textured fried puffed food The production line is automatically completed from mixing, extrusion, to frying and seasoning. The configuration is reasonable, the degree of automation is high, the performance is stable, the shape of the produced product is more realistic, the texture is more delicate after frying, and the taste is crispy. Our screw combination technology and precise control of the production process enable wider selection of raw materials, better product quality and more varieties.

隐藏域元素占位

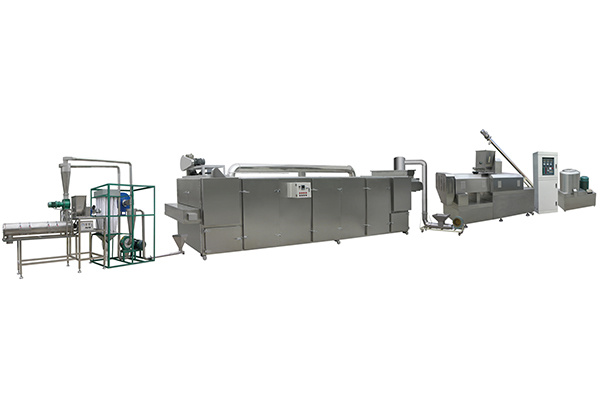

Nutrition powder production line

The production line of five-grain nutritional powder uses corn flour, rice flour, millet flour, brown rice flour, wheat flour and other whole grain powder as the main raw materials, with vegetables, fruits, eggs, meat and other optional ingredients, adding calcium, phosphorus, iron and other minerals And vitamins, etc., through mixing, extrusion, drying, crushing and other processes to gelatinize the grain starch and ripen the protein, and process it into five grain nutrition powder, infant nutrition rice flour and other products. The production line has the characteristics of high degree of automation, strong stability, simple operation, high output, short process time, etc., and has effectively improved various drawbacks in the original tradition. It is widely used in various breakfast cereals, baby rice noodles, sesame paste and walnut paste products. It is a new type of high-efficiency nutritional rice flour production line.

隐藏域元素占位

The golden rice production line equipment mainly adopts twin-screw extrusion technology; this production technology uses rice flour, corn flour and other whole grains as the main raw materials, and at the same time, various nutrients necessary for human health such as vitamins, minerals and dietary fiber can be added in proportion etc. Extrude and granulate through a twin-screw extruder to produce nutritionally fortified rice. This processing technology not only retains the original ingredients of ordinary rice, but also supplements and strengthens the nutrients necessary for human health that are lost in the fine processing of rice; it can also produce coarse grains carefully to produce miscellaneous grains rice. The output of the production line ranges from 200 kg to 2000 kg/hour, customized according to customer needs, and realizes the PC visual automation control of the entire production line.

隐藏域元素占位

Self-heating rice production line

自加热米生产线设备主要采用双螺杆挤压膨化技术;该生产技术以大米粉、玉米粉等五谷杂粮为主要原料,同时可按比例添加人体健康所必需的各种营养素如维生素、矿物质及膳食纤维等,通过双螺杆挤出机挤出造粒,生产营养强化米。此加工技术既保留了普通大米的原有成分,又补充和强化了大米精加工流失而人体健康所必需的营养素;还可粗粮细作,生产杂粮米。生产线的产量从200公斤到2000公斤/小时不等,根据客户需求定制,实现整条生产线PC可视自动化控制。

隐藏域元素占位

The wheat burning production line is composed of a feeding system, an extrusion system, a rotary cutting system, a heating system, a transmission system, and a control system. The advanced screw extrusion and expansion technology uses high temperature and high pressure to mature and expand the material, which is completed at one time. The main engine adopts frequency conversion speed regulation to ensure the stability of the production process. The products have various colors and varieties, beautiful appearance, natural and lifelike, delicate texture, and high-quality raw materials.

隐藏域元素占位

Sandwich rice cracker and rice cake production line

The production line of sandwich rice crackers and rice cakes is completed at one time from raw material preparation, extrusion puffing, sandwiching, forming, cutting, spraying, seasoning to finished products, with a high degree of automation. The production line has the characteristics of multiple models, flexible configuration, wide range of raw materials, many types of products, and simple operation. Selecting the appropriate configuration can produce sandwich rice crackers, rice cakes, wheat roast, wheat-flavored chicken nuggets and other products. The puffed food has a crisp taste, easy to digest, unique fragrance, and is easy to carry. It is an ideal snack food for consumers.

隐藏域元素占位

The production line is complete from raw material preparation, extrusion and puffing, forming, cutting, baking, spraying, seasoning to finished product at one time, with a high degree of automation. The production line has the characteristics of multiple models, flexible configuration, wide range of raw materials, many types of products, and simple operation. The production line configuration can produce baked bread slices with flour as the main raw material. Adding several production equipment can produce Taiwan rice cakes , sandwich tubes, sandwich rice crackers, Mai Shao, Mai Xiang chicken nuggets, nutritious breakfast, corn flakes and other products. The puffed food has a crisp taste, easy to digest, unique fragrance, and is easy to carry. It is an ideal snack food for consumers.

隐藏域元素占位

News content

Quality control is an essential aspect of the Bugle Doritos production line. Inspections are carried out at various stages

隐藏域元素占位