27

2025

-

04

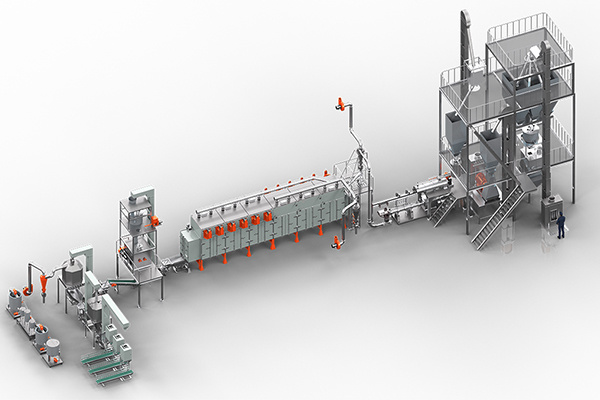

Bugle Doritos Production Line

Author:

2025-04-27 15:11

Bugle Doritos are a popular snack known for their unique shape and delicious taste. These snacks have a large consumer base, and understanding Bugle Doritos Production Line is crucial for both the producers and consumers interested in the manufacturing process.

The Bugle Doritos Production Line starts with carefully selected raw materials. The main ingredients typically include cornmeal, which provides the base structure. Alongside cornmeal, various seasonings are used to give Bugle Doritos their distinct flavor. For example, cheese powder, salt, and spices are crucial components. The quality of these raw materials directly impacts the final taste and texture of the Bugle Doritos.

The Production Process

- Mixing: The first step in the production line is the mixing of the raw materials. Cornmeal and other dry ingredients are combined in precise proportions. This mixture needs to be well-blended to ensure uniformity in every Bugle Dorito.

- Shaping: After mixing, the dough-like mixture is sent to the shaping machines. Here, the characteristic bugle-shaped pieces are formed. This step requires precise machinery to create the consistent shape that Bugle Doritos are known for.

- Frying: Once shaped, the Bugle Doritos are then fried. Frying is a critical step as it gives the snacks their crispy texture. The temperature and time of frying are carefully controlled to achieve the perfect level of crispiness without overcooking.

- Seasoning: After frying, the Bugle Doritos are seasoned. This is where the unique flavors are added. The seasonings are evenly distributed over the surface of the snacks to ensure a consistent taste in every bite.

Quality control is an essential aspect of the Bugle Doritos production line. Inspections are carried out at various stages. The shape, size, and color of the Bugle Doritos are checked to ensure they meet the standards. Additionally, the taste and texture are also evaluated. Any products that do not meet the quality criteria are removed from the production line. This strict quality control helps to maintain the high-quality reputation of Bugle Doritos.

Other news

【 Event Invitation 】 Jinan Chenyang Technology (N6R67) invites you to join us at the Shanghai Asian Pet Expo, creating a new era in the pet food industry

2024-08-15

Understanding the Role of Pet Food Extruders in the Pet Food Industry

Pet food extruders are specialized machines that play a crucial role in the production of various types of pet food, ranging from dry kibble to wet food options. The extruder operates through a process known as extrusion, which involves cooking and shaping raw ingredients under controlled temperature and pressure conditions. This method not only enhances the nutritional profile of the food but als

2025-12-12

Unlocking Pet Nutrition: The Essential Role of Extruders in Pet Food Manufacturing

Unlocking Pet Nutrition: The Essential Role of Extruders in Pet Food Manufacturing Table of Contents Introduction to Pet Nutrition and Manufacturing Understanding the Extrusion Process in Pet Food Benefits of Extrusion in Pet Food Production Types of Extruders Used in Pet Food Manufacturing Selecting Raw Materials for Extrusion The Impact of Extrusion on Pet Nutrition Sustainability

2025-12-09

Understanding the Functionality and Importance of Cat Food Extruders in Pet Food Manufacturing

Cat food extruders are crucial machines in the pet food manufacturing industry, particularly for the production of dry cat food. These machines are designed to convert raw ingredients into a palatable and digestible product through a process known as extrusion. The technology behind cat food extruders involves a combination of mechanical and thermal processes, which help create the desired texture

2025-12-06