Label navigation

Cheerios processing machine

Cheerios processing machines are designed to transform raw materials, primarily whole grain oats, into finished cereal products. The process typically begins with the cleaning and conditioning of the oats. Effective cleaning is crucial as it removes impurities and ensures that only the best quality grains are used. Automated systems are often employed to streamline this process, leading to enhanced efficiency and reduced labor costs.

Product content

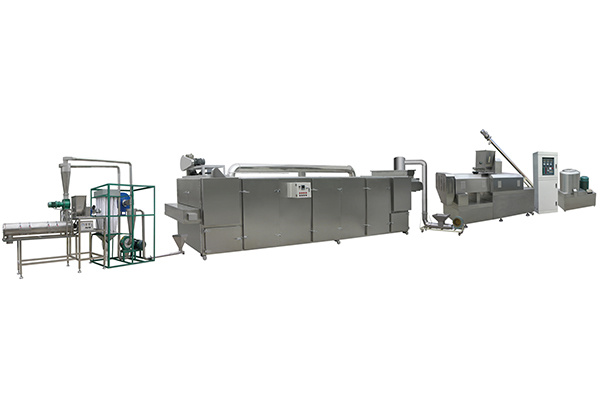

Nutrition powder production line

The production line of five-grain nutritional powder uses corn flour, rice flour, millet flour, brown rice flour, wheat flour and other whole grain powder as the main raw materials, with vegetables, fruits, eggs, meat and other optional ingredients, adding calcium, phosphorus, iron and other minerals And vitamins, etc., through mixing, extrusion, drying, crushing and other processes to gelatinize the grain starch and ripen the protein, and process it into five grain nutrition powder, infant nutrition rice flour and other products. The production line has the characteristics of high degree of automation, strong stability, simple operation, high output, short process time, etc., and has effectively improved various drawbacks in the original tradition. It is widely used in various breakfast cereals, baby rice noodles, sesame paste and walnut paste products. It is a new type of high-efficiency nutritional rice flour production line.

隐藏域元素占位

Fried tartary buckwheat flakes, buckwheat flakes production line

The fried puffed food production line uses flour, corn flour, corn starch, tapioca starch, potato starch, etc. as raw materials, changes different molds, and is directly extruded by a twin-screw extruder to cut into special-shaped composite products such as strips, flakes, or triangles. Fried and seasoned to make crispy, delicious, fine-textured fried puffed food The production line is automatically completed from mixing, extrusion, to frying and seasoning. The configuration is reasonable, the degree of automation is high, the performance is stable, the shape of the produced product is more realistic, the texture is more delicate after frying, and the taste is crispy. Our screw combination technology and precise control of the production process enable wider selection of raw materials, better product quality and more varieties.

隐藏域元素占位

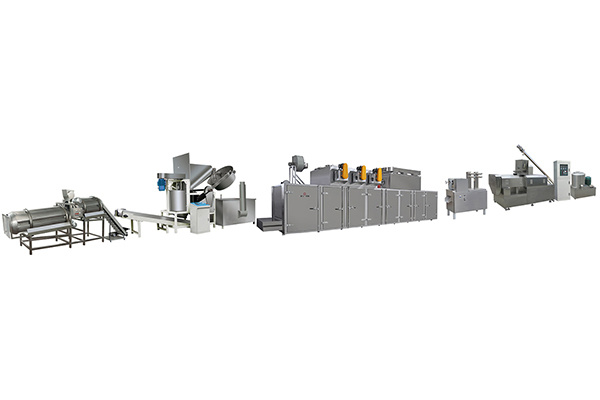

Fried crispy rice, salad bar, Miao crispy corner production line

The production line of deep-fried crispy rice, salad bars, and crispy crispy is a new technology that uses twin-screw extrusion technology to replace the traditional steamed rice crispy production. The production line integrates raw material mixing, cooking, ripening, puffing, molding, frying, and seasoning, and does not require a boiler. The production process is simplified, efficient, and environmentally friendly; the raw materials can be rice flour, corn flour, flour, etc. These mixed materials; the shape of the product can be changed by changing the mold, and the produced pasta crispy rice, salad, etc. are crispy and not greasy, and are widely loved by consumers.

隐藏域元素占位

News content

Optimizing the Production Process: Insights into Cheerios Processing Machines

Cheerios processing machines are designed to transform raw materials, primarily whole grain oats, into finished cereal products.

隐藏域元素占位

Maximizing Efficiency in Grain Processing with Cheerios Processing Machines

In the realm of agricultural machinery, Cheerios processing machines play a pivotal role in the efficient transformation of raw grains into popular breakfast cereals. These machines are specifically designed to handle various processes, including milling, mixing, and cooking, ultimately contributing to the production of finished cereal products that meet consumer demand. Understanding the function

隐藏域元素占位

Understanding Cheerios Processing Machines: Innovations in Grain Processing

The Cheerios processing machine represents a significant advancement in the grain processing industry, particularly for manufacturers focusing on cereal production. These specialized machines are designed to efficiently transform raw grains into the popular breakfast cereal known as Cheerios, employing a series of intricate steps that ensure quality and consistency. At the heart of the Cheerios pr

隐藏域元素占位