25

2025

-

09

Optimizing the Production Process: Insights into Cheerios Processing Machines

Author:

2025-09-25 09:30

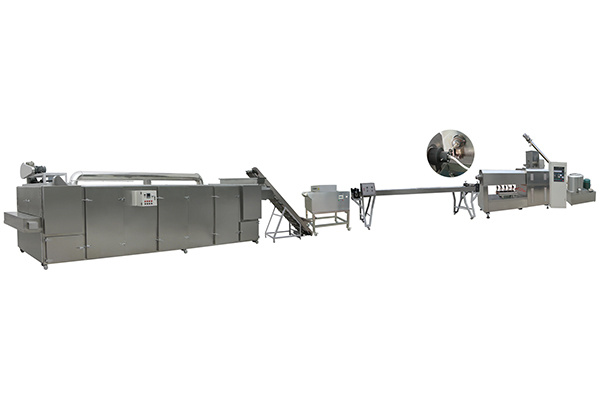

In the agricultural food machinery industry, the Cheerios processing machine plays a pivotal role in the production of this popular breakfast cereal. Understanding how these machines operate and their various components can significantly enhance productivity and product quality.

Cheerios processing machines are designed to transform raw materials, primarily whole grain oats, into finished cereal products. The process typically begins with the cleaning and conditioning of the oats. Effective cleaning is crucial as it removes impurities and ensures that only the best quality grains are used. Automated systems are often employed to streamline this process, leading to enhanced efficiency and reduced labor costs.

After cleaning, the oats undergo a steaming process. This step is essential as it gelatinizes the starches, making them more digestible and enhancing the final product's texture. The steaming is closely monitored, as the right time and temperature are vital to ensure the oats retain their nutritional value while achieving the desired consistency.

Once steamed, the oats are subjected to a milling process. This involves grinding the oats into a fine flour, which can then be mixed with other ingredients, such as sugars and flavors, depending on the desired cereal variety. The milling process must be precisely controlled to achieve the correct particle size, which directly affects the cereal’s final texture and taste. Advanced milling technology is commonly incorporated into Cheerios processing machines, allowing for consistent and uniform results.

The next stage is extrusion, where the mixture is pushed through a die at high temperatures and pressures. This process expands the mixture, giving Cheerios their characteristic shape and crunch. The extrusion process is a crucial part of the overall operation; therefore, investing in high-quality extruders tailored for Cheerios production can lead to significant improvements in product quality and operational efficiency.

After extrusion, the cereals are dried to remove excess moisture, which is essential for shelf stability. Proper drying techniques help prevent spoilage and maintain the cereal’s crispness. Following drying, the Cheerios are cooled and often coated with additional flavors or nutrients before packaging.

In summary, understanding the intricacies of Cheerios processing machines is vital for professionals in the agricultural food machinery sector. By focusing on each step of the production process—from cleaning and steaming to milling, extrusion, and drying—manufacturers can optimize their operations and produce high-quality cereals that meet consumer demands. Continuous advancements in technology are expected to further enhance the efficiency and effectiveness of these processing machines, ensuring that the production of Cheerios remains competitive in the evolving food industry landscape.

Other news

【 Event Invitation 】 Jinan Chenyang Technology (N6R67) invites you to join us at the Shanghai Asian Pet Expo, creating a new era in the pet food industry

2024-08-15

Extruded Corn Snacks Market Expands as Food Processors Upgrade to Advanced Extruded Food Dryers

Demand for extruded corn snacks is rising globally as producers adopt advanced extruded food dryers to improve efficiency, quality, and energy savings.

2025-12-04

Creating Pet Food Products for Special Diets Using Extrusion: A Comprehensive Guide

Creating Pet Food Products for Special Diets Using Extrusion: A Comprehensive Guide Table of Contents Understanding Extrusion Technology in Pet Food Production The Importance of Special Diets for Pets Key Ingredients for Special Diet Pet Foods The Extrusion Process Explained Quality Control in Pet Food Extrusion Formulating Recipes for Special Diets Packaging and Marke

2025-12-03