Nutrition powder production line

Category:

key word:

Product details

1. Product overview: The nutritional powder/meal replacement powder/instant rice flour production line uses rice, corn, beans and various grains as raw materials. Through extrusion, puffing, drying, crushing and mixing, a variety of nutritional powders can be produced, such as baby rice powder, meal replacement powder, whole grain powder, instant corn flour, modified starch, etc. This line can automate all processes from feeding to finishing. It has the characteristics of easy operation, no dust leakage, sanitation, energy saving, and easy addition of various raw materials and nutrients.

Extruded nutritional powder and meal replacement powder use a twin-screw extruder to recombine the starch structure and organizational state of various grain raw materials, dietary fiber and other nutritional components through the extrusion process.

The instantaneous high temperature and high pressure and puffing effect of the extrusion process can not only change the structural characteristics of the material, promote the gelatinization of starch, instantly weaken the pressure to change the structure of miscellaneous grains, solve the problems of poor taste and difficulty in digestion of miscellaneous grains, but also better Retain nutritional components, sterilize and sterilize.

Compared with the raw miscellaneous grain powder, the extrusion treatment enhanced the thermal stability of the miscellaneous grain powder, weakened the degree of shear thinning of the paste, was not easy to age and retrograde, and improved the freeze-thaw stability. It is fine and porous, so as to achieve the effect of rapid rehydration.

At present, the main uses are: making puffed nutrition powder, puffed meal replacement powder, puffed cake powder, etc. Among them, puffed nutrition powder and meal replacement powder are mainly used for direct consumption, replacing some staple foods, and supplementing energy, while puffed cake powder is used for making various pastries to improve the flavor and taste of the product. In addition, it can also be used to produce products such as puffed modified starch by changing the parameters of the equipment and replacing the raw materials. Modified starch is widely used in textile, food processing, oil drilling, paper making, construction industries, etc.

2. Process flow: raw material mixing-extrusion puffing-drying-crushing-mixing-packaging

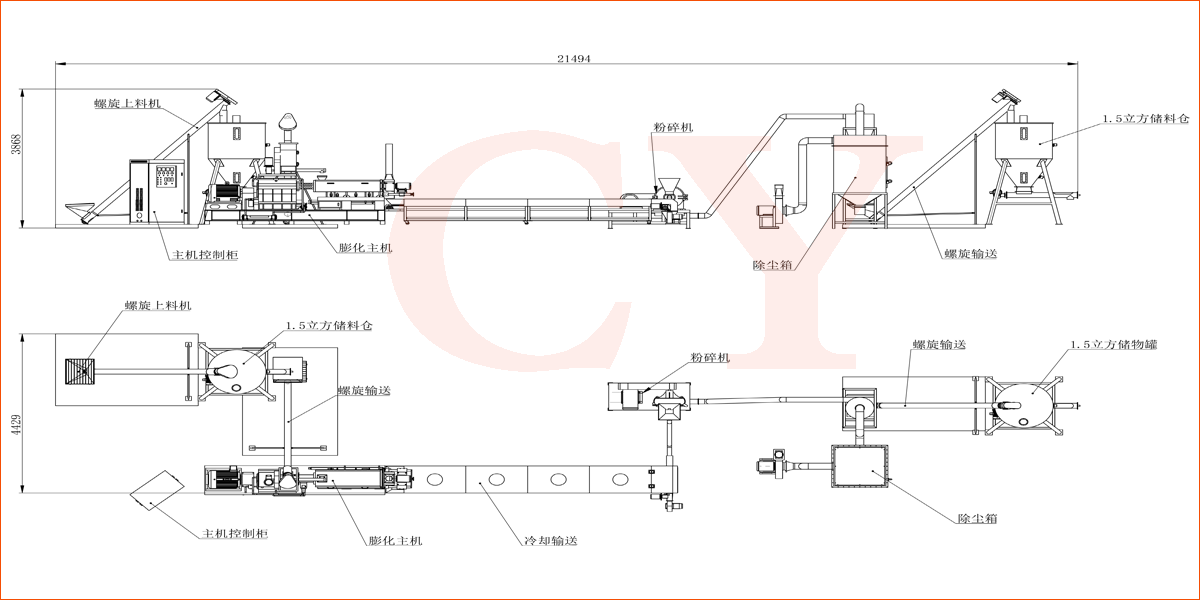

3. Equipment composition: powder mixer→screw feeder→extruder→air conveyor→dryer→dust collector→batch mixer→packing machine

4. Product parameters:

5. Plane layout:

6. Sample display:

7. After-sales service:

A. Provide basic formula;

B. Equipment warranty for one year;

C. Provide plant design;

D. Responsible for installation and commissioning;

E. Responsible for personnel training.

Online Message