McNuggets Production Line

Category:

key word:

Product details

1. Product overview: The production line of Maixiang chicken nuggets is completed at one time from raw material preparation, extrusion, forming, cutting, baking, spraying, seasoning to finished product, with a high degree of automation. The production line has the characteristics of multiple models, flexible configuration, wide range of raw materials, many types of products, and simple operation. The production line configuration can produce baked bread slices with flour as the main raw material. Adding several production equipment can produce Taiwan rice cakes , sandwich tubes, sandwich rice crackers, Mai Shao, Mai Xiang chicken nuggets, nutritious breakfast, corn flakes and other products. The puffed food has a crisp taste, easy to digest, unique fragrance, and is easy to carry. It is an ideal snack food for consumers.

2. Process flow: raw material mixing-transportation-expansion molding-sandwich cutting-baking-seasoning-cooling packaging

3. Equipment configuration: flour mixing machine-screw conveyor-twin-screw extruder-multi-layer oven (fryer)-seasoning line-cooling conveyor-packing machine

4. Equipment details:

● Mixing machine: Mix the powdered raw materials according to the formula ratio, and select a suitable mixing machine according to the output of the production line and the viscosity of the raw materials.

● Feeding machine: The motor is used as the driving force for screw conveying, and the mixed raw materials are conveyed to the feeding hopper of the extrusion extruder with a certain height to ensure convenient and fast feeding.

● Twin-screw extruder: choose different types of YS65-111 extruders according to the output of the production line, the output can range from 100kg/h--1000kg/h, and different types of extruders can be selected according to the products

● Cutting machine: cutting strips and flakes of fried products, cutting baked products such as Maishao and rice crackers

● Sandwich machine: to inject fillings for sandwich rice crackers, you can add chocolate, cream, egg yolk, peanut butter, jam, etc.

● Cooling hoist conveying: automatic conveying of each equipment product, according to the needs of different puffed products, there are PVC conveyor belts and stainless steel conveyor belts to choose from, and processing and customization according to output and plant restrictions

● Multi-layer oven: Non-fried puffed food is baked to make the product more crispy, tasty, and increase the taste. At the same time, the moisture of the material is dried to increase the shelf life. Ovens can be divided into climbing ovens and ordinary ovens according to the configuration requirements of the production line. Electric heating, natural gas heating, and steam heating can be selected according to the energy source. According to the drying temperature, high-temperature drying oven and low-temperature drying oven can be selected, and circulation structure and constant current structure can be selected according to the internal structure. The temperature can be adjusted by the control cabinet between 0-200 degrees. The part in contact with the puffed food is made of stainless steel. The baking time can be adjusted according to the speed.

● Frying machine: Fried small puffed food needs to have good product shaping properties and high water content during puffing. After being formed by the puffing machine, it will directly enter the frying machine for frying, dehydration and finalization to make the product crispy. The frying machines of Chenyang Company include semi-automatic frying machines, tunnel type, continuous frying machines, and double-layer belt type tunnel frying machines (puffed food that sinks before and floats after). The deoiler has a single cylinder deoiler and a double cylinder deoiler. Meet the needs of semi-automatic and automatic continuous production.

● Seasoning line: There are octagonal cylinder, single-drum and double-drum seasoning lines, configured according to output and product properties, and oil spraying, sugar spraying and coating equipment. In order to meet the needs of market development, our company has developed batch weighing seasoning and mixing equipment, single-head star anise seasoning machine, double-head star anise seasoning machine, forward and reverse seasoning machine. The uniformity of product mixing and the precise control of the amount of seasoning added are improved.

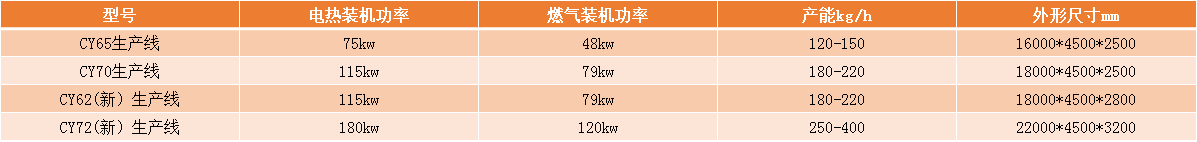

5. Product parameters:

6. Sample display:

7. After-sales service:

Online Message