Aquatic feed production line

Category:

key word:

Product details

Industry Background: With the development of aquaculture industry to scale, intensification and modernization, the requirements for aquatic feed are becoming higher and higher. The traditional powdered compound feed, granular compound feed and other types of compound feed all have disadvantages such as poor stability in water, fast settling speed, easy to cause feed loss and water pollution, which have become more and more unsuitable for the development of modern aquaculture industry. And expanded fish feed to solve these drawbacks, more and more aquaculture farmers and feed plant installed expanded feed equipment.

1, product overview: aquatic feed production line with flour, corn meal, soybean meal, meat meal, fish meal, bone meal and other raw materials, with automatic mixing system to achieve automatic scientific mixing, twin screw extruder extrusion of various shapes, then drying, spraying can produce a variety of shapes, balanced nutrition, palatability good formula pet food; Twin-screw extrusion technology can produce pet food, which can retain the nutritional ingredients in the formula, easy to digest and absorb, and easy to change the shape of the formula. The whole assembly line configuration optimization, high degree of automation, precise control of the production process, stable product quality, high production efficiency, health and environmental protection; Degu provides a variety of configurations and output, can produce dog food/cat food/bird food/fish food/aquatic feed production line for your choice!

2. Process flow: powder mixer → screw feeder → (modulation) twin-screw extruder → air feeder → multi-layer dryer - roller oil injection machine

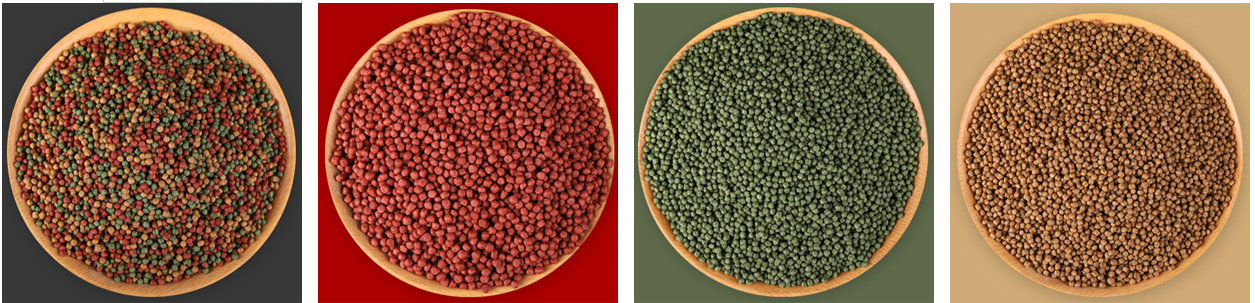

3, product type: can produce and process catfish, grass carp, crucian carp, tilapia, ornamental fish, turtle, bullfrog and other aquarium feed particles

4. Ingredient process: Ingredient is to ensure the accurate implementation of various raw material components of the formula, so as to ensure the nutritional balance of feed, and to reduce the classification after mixing as much as possible. The new mixer can realize efficient mixing and guarantee the quality of feed products. Steam conditioning of feed can improve the gelatinization degree of starch, denaturate protein and improve digestibility of feed. In addition, conditioning is also beneficial to granulation, bulking and particle durability of feed, reducing feed loss in transportation and water, and improving feed utilization rate. Extrusion processing is the preferred processing method of aquatic feed because the temperature and pressure conditions are stronger than granulation and expansion, which can better improve the digestibility and utilization rate of these animal feeds.

5. Product parameters:

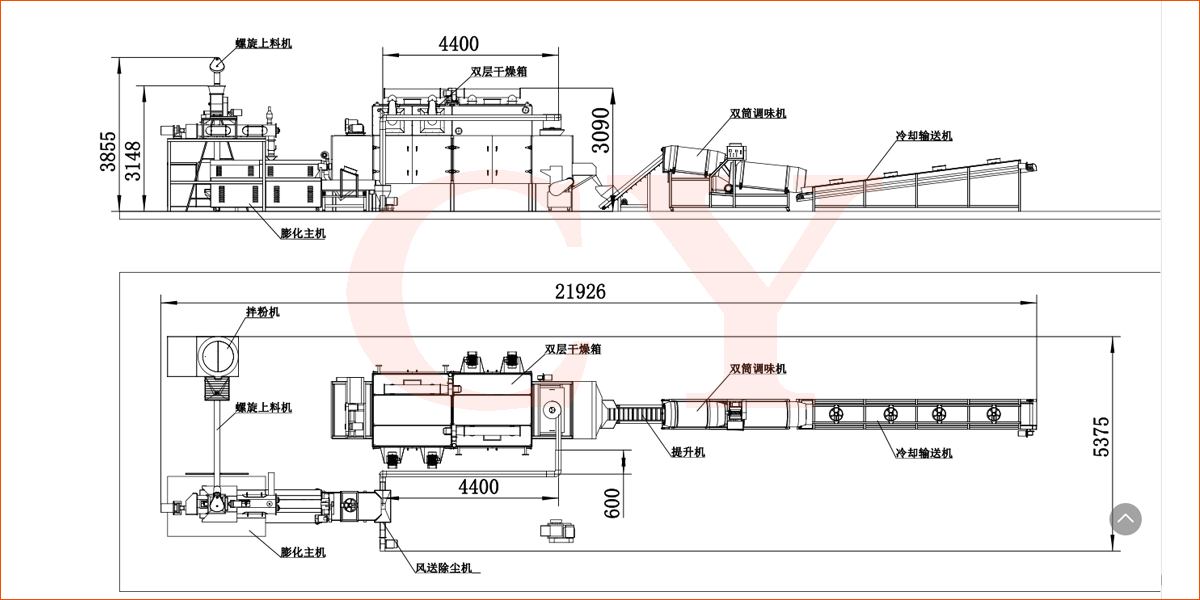

6. Plane Layout:

7. Sample display:

8. After-sales Service:

A. Provide basic formula;

B. Equipment warranty for one year;

C. Provide plant design;

D. Responsible for installation and debugging;

E. Responsible for personnel training.

Online Message