17

2025

-

06

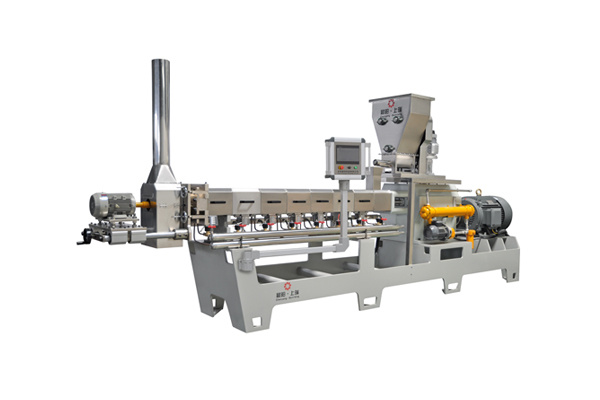

Artificial rice extruder

Author:

2025-06-17 11:00

Artificial rice extruders are specialized machines designed to create rice-like products from various raw materials. These extruders play a pivotal role in the food processing industry, particularly in the manufacture of alternative rice products, which can cater to diverse consumer demands. Understanding how to effectively use an artificial rice extruder can significantly enhance production efficiency, product quality, and overall business profitability.

One of the primary advantages of using an artificial rice extruder is its versatility. These machines can process a range of materials, including corn, wheat, and other grains, enabling manufacturers to create a variety of rice-like products tailored to consumer preferences. This adaptability is particularly useful in a market that increasingly seeks gluten-free and healthier alternatives.

In terms of operational efficiency, an artificial rice extruder allows for continuous processing, which can streamline production lines and reduce labor costs. The process involves feeding raw materials into the extruder, where they are subjected to high temperatures and pressures. This not only cooks the ingredients but also alters their structure, resulting in the formation of rice-like grains that mimic the texture and appearance of traditional rice. By optimizing parameters such as temperature, moisture content, and extrusion speed, manufacturers can achieve consistent product quality.

Moreover, the extrusion process enhances the nutritional profile of the final product. By fortifying the raw materials with essential vitamins and minerals during the extrusion phase, manufacturers can produce enriched rice alternatives that appeal to health-conscious consumers. This added value can create differentiation in a competitive market, allowing brands to stand out.

When investing in an artificial rice extruder, it's important to consider factors such as capacity, energy efficiency, and ease of maintenance. Selecting the right machine that aligns with your production goals can lead to significant long-term benefits. Regular maintenance of the extruder is also crucial to ensure optimal performance and longevity of the equipment.

In conclusion, integrating an artificial rice extruder into your food processing operations can unlock new opportunities for product innovation and market expansion. By understanding its functionalities and best practices, manufacturers can enhance their production capabilities and respond effectively to evolving consumer trends. As the demand for alternative rice products grows, leveraging this technology may position your business at the forefront of the industry.

Other news

【 Event Invitation 】 Jinan Chenyang Technology (N6R67) invites you to join us at the Shanghai Asian Pet Expo, creating a new era in the pet food industry

2024-08-15

Extruded Corn Snacks Market Expands as Food Processors Upgrade to Advanced Extruded Food Dryers

Demand for extruded corn snacks is rising globally as producers adopt advanced extruded food dryers to improve efficiency, quality, and energy savings.

2025-12-04

Creating Pet Food Products for Special Diets Using Extrusion: A Comprehensive Guide

Creating Pet Food Products for Special Diets Using Extrusion: A Comprehensive Guide Table of Contents Understanding Extrusion Technology in Pet Food Production The Importance of Special Diets for Pets Key Ingredients for Special Diet Pet Foods The Extrusion Process Explained Quality Control in Pet Food Extrusion Formulating Recipes for Special Diets Packaging and Marke

2025-12-03